The first step of the Lifecycle begins when equipment and components are onboarded into the PCR module.

Planned Component Replacements (PCR) by AMS

A better way to manage component lifecycles!

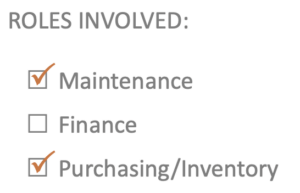

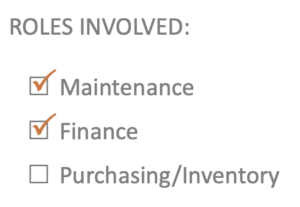

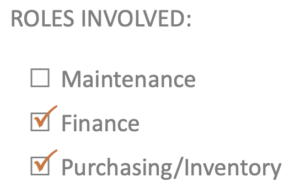

Managing rebuildable equipment components in JD Edwards requires seamless coordination across maintenance, purchasing, and finance teams. The existing process can be cumbersome, requiring shared master data and manual tracking of each component’s lifecycle. We tackled this challenge by developing a simple, user-friendly solution that streamlines the fit/defit process, core tracking, and financial management.

Because Every Component Swap Should Be Easy, Clear & Trackable

A Fit/Defit WO is generated to remove the used-up component and install the new component, returning the equipment to production. The defitted component is evaluated to determine if it can be rebuilt or needs to be disposed.

The defitted component can be rebuilt internally or sent out to a vendor to be rebuilt or replaced.

The newly rebuilt or replacement component is placed back into inventory, ready to be fitted into another piece of equipment. Newly purchased component spares are onboarded and placed into inventory as well.

As the operating component approaches the end of its planned life, the warehouse is notified to release a new component to be installed (Fitted).

Because Every Component Swap Should Be Easy, Clear & Trackable

Our PCR Solution Saves You Time & Money

The AMS Planned Component Replacements module includes the following key capabilities:

Component Lifecycle Tracking

Fit/Defit Process Management

Core & Capital Spares Management

Rebuild Coordination

Automated Financial Transactions

Newly built plants and equipment fleets are designed with replaceable components. Over time, these components wear out and require a smooth cycle of removal, replacement, rebuilding, and reintegration. PCR ensures that every component is accounted for, minimizing downtime and maximizing operational efficiency.

Instead of relying on disjointed processes, AMS’s PCR module provides real-time tracking, simplifies decision-making, and eliminates manual frustrations. Your team can now confidently manage component replacements with greater accuracy and efficiency.

Finally, your organization can answer these critical questions with ease:

- What is the average lifespan of the components used throughout the equipment’s lifecycle?

- How many times has a specific component been rebuilt, and when should the core be returned to the OEM or a new component procured?

Say goodbye to manual tracking and uncertainty—AMS PCR makes component management seamless.

Check Out Our Other Solutions...